CAD

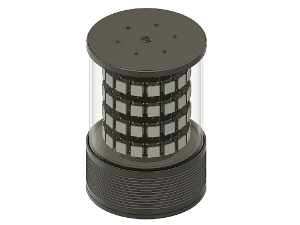

Most of our products start as a 3D drawing and is then expanded and refined. We use SolidWorks and Fusion 360 as our CAD tools. A lot of early development is around 3D models to make sure we get the form, fit and function correct before we start to spend money.

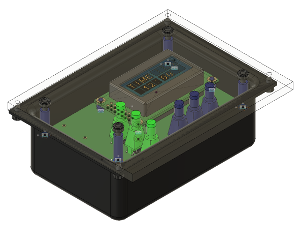

Most of our prototypes are mocked-up in 3D with renderings. This gives clients a much clearer picture of what they will get and help to steer the design to proper prototype without wasting time and resources.

Some of our more complex products demand that we check fit and manufacturability before we send items away to be made.